DFAM: Accelerating Innovation Across Industries

We have 20+ years of experience, from minimalist design to intricate details, we can help you grow your brand.

What is DFAM?

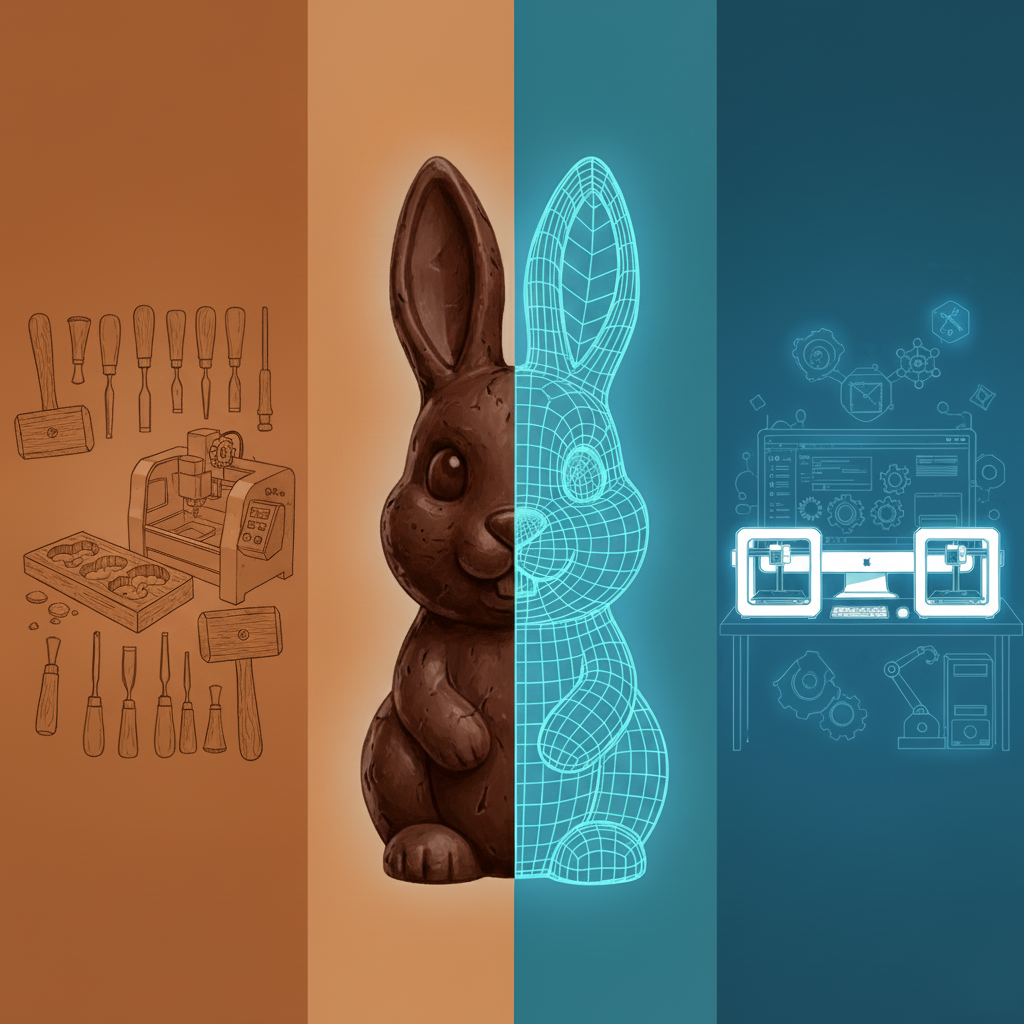

DFAM (Design for Additive Manufacturing) means designing specifically for 3D printing.

It’s not just about modeling, it’s about optimizing shape, structure, and performance to make sure your product prints efficiently and functions reliably.

At Real Volume, we tailor every design to the strengths of additive manufacturing. That means fewer supports, better part strength, and production-ready files.

Skills:

Optimized designs for modern manufacturing

DFAM (Design for Additive Manufacturing)

Jigs & multi-part assemblies

Freeform to complex feature design

End-to-end workflow: concept art, 3D modeling, file prep

High-quality meshes (up to 50M polygons)

Industry standard NURBs (CAD) files for high production injection molding

Specific areas of expertise

Resource optimization: Time and resource optimization through slicing analysis

Creation of manufacturing files: Helping you understand the best file types for specific projects

Product adaptation: From prototype to DFAM

Product design and design method optimization: Creating a design method that is cost effective and time efficient

CAD and mesh fixing, splitting, keying (bigger or special parts)